In our July monthly newsletter (if you missed it, you can subscribe for our monthly update here) we wrote about capturing LEED credits for carefully documenting the project’s framing lumber requirements and then ordering only what is needed.

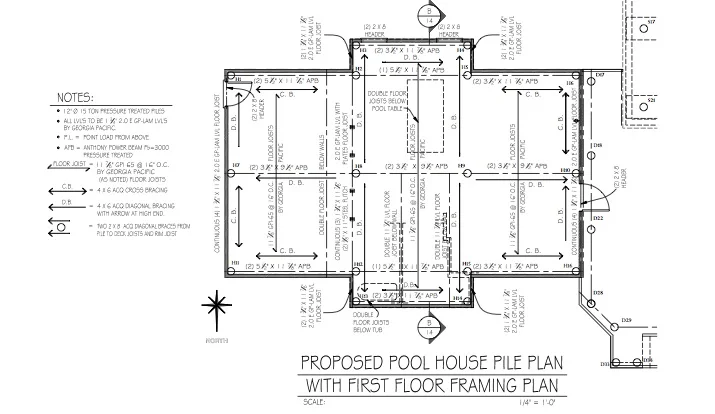

Bill Heine, our architect, created detailed framing documents for the project and then Chris Mensch, our builder, translated the framing plans into a exact cut list and lumber order for the project's framing. LEED for Homes awards two points toward our certification for including these elements.

A sample section of Sunset Green Home's Pool House Framing Plan

Why are these important?

According to the LEED for Homes Reference Guide, "a major challenge in new home construction is determining the amount of framing materials needed for a project. Often, the amount of lumber ordered greatly exceeds what is actually needed." In order to discourage such waste, which typically ends up in a landfill or needlessly incorporated into a building's framing, LEED for Homes rewards projects that carefully specify a framing plan and then order lumber to meet the precise needs of the project. Not only do we earn two points toward our LEED certification, but we will also save on the cost of framing materials ordered for the project. That's a double win for Sunset Green Home!

But ordering the right quantity of lumber is only one way that Sunset Green Home will earn LEED credits for framing. Before we even arrived at a lumber order, Bill Heine incorporated several “Efficient Framing Measures” into the home’s framing design. Not only do these measures save in terms of framing material required, but according to LEED for Homes, “reduced framing can reduce the number and size of thermal breaks and increase the amount of insulation installed, leading to better energy performance.”

So what is meant by Efficient Framing Measures? LEED for Homes identifies the following:

- Precut framing packages

- Open-web floor trusses

- Structural insulated panel (SIP) walls

- SIP roof, SIP floors

- Stud spacing greater than 16” o.c.

- Floor joist spacing greater than 16” o.c.

- Roof rafter spacing greater than 16” o.c.

- Implement 2 of the following:

- Size headers for actual loads

- Use ladder blocking or drywall clips

- Use 2-stud corners

The U.S. Department of Energy has published an Advanced Wall Framing Technology Fact Sheet, which provides illustrations and detailed descriptions of several of the advanced framing techniques that are eligible for LEED for Homes credits.

Because of hurricane considerations (the topic of an upcoming article), Sunset Green Home will not pursue some of the more material efficient framing measures (such as wider stud spacing) that might be appropriate for an inland project. However, Sunset Green Home will earn credit toward our certification by “sizing headers for actual loads” and using “ladder blocking” where interior walls intersect the exterior walls of the house.

In fact, the framing crew has already included both measures in the framing of the pool house. Here’s a photo of ladder blocking in the pool house. You can see that there is a space behind the “ladder” to which the stud is attached – and that space will be filled with insulation, giving Sunset Green Home a tighter building envelope and providing for greater energy efficiency.

Ladder blocking where an interior wall intersects the exterior wall saves materials and preserves space for insulation to be installed

And here is a photo showing headers above the pool house door and two windows. Header sizes depend on how great a load they must bear. This door header is constructed from two 11 7/8” LVL (laminated veneer lumber) beams to carry the load of the flitch plate ridge above (a flitch plate is a steel plate sandwiched between two wooden beams to give the beam greater strength). The window headers, which carry a lower load, are built from two pieces of 2x8 Douglas fir lumber.

Window and door headers of varying sizes in Sunset Green Home's pool house framing

Together with the credits we’ll earn for creating detailed framing documents and a corresponding lumber cut list, we can add 2.5 points toward Sunset Green Home’s LEED certification. And, having created a detailed lumber order based only on what we needed, we’re happy to be reducing the project’s waste at the same time.

Many LEED strategies make good financial sense while they also result in greater energy efficiency and less impact on the environment. Material Efficient Framing is a perfect example!