Nearly all of Sunset Green Home’s windows have been installed as of this chilly Friday morning. And the roof of the main house is almost complete (we’ve had a few rainy days recently, and nobody wants the roofers on a slippery wet roof!).

Jim Hunter of JP Hunter Co., Sunset Green Home’s roofing subcontractor provided some terrific aerial photographs of Sunset Green Home’s roof under construction. The photos show the beauty of Anbrook Industries’ taper sawn Western Red Cedar shingles.

Photo courtesy JP Hunter

But we also got up close to see how the roof was being constructed and the windows installed.

In an earlier article, we discussed in detail the many layers that comprise Sunset Green Home’s high performance roof assembly. The slide show below shows the materials that comprise Sunset Green Home's beautiful, energy efficient and durable roof.

Up on the roof we were able to see how all of the components interact. In this photo, lead coated copper flashing is installed in the valleys and around the chimney to defeat the forces of gravity, wind and surface tension on areas of the roof that might be susceptible to water intrusion.

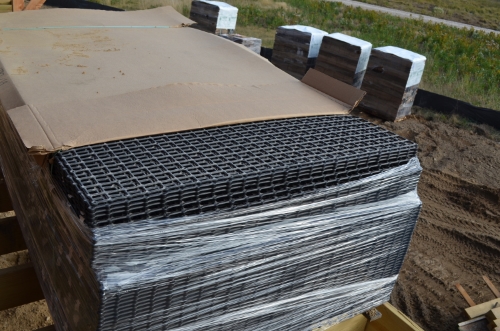

Underneath those durable taper sawn Anbrook shingles, and atop the lead coated copper flashing, the roofers have installed Grace Ice & Water Shield at rakes, eaves and other areas where ice damming might occur. They installed a layer of Ventgrid12™ a product made from post-consumer recycled content that acts as a drainage plane and air gap - allowing the shingles to breathe and letting any water that gets behind the shingles drain downward and away from the roof structure.

While JP Hunter's team has been up on the roof, the crew from Coastal Management, Sunset Green Home’s builder, has been in the house installing the home’s impact resistant Integrity Wood Ultrex windows by Marvin. The photo below shows windows in various stages of installation. The opening at the top center has received a layer of Grace Ice & Water Shield at the sill, which is installed before the window.

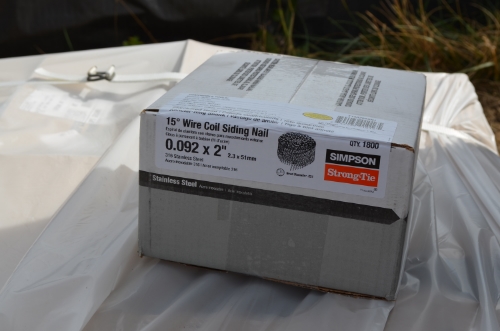

The window crew installed flanges (also known as nailing fins) around each window, and the structural brackets that are required for the special impact-resistant windows used in the project.

The team applied a bead of caulk around the exterior of the window and lifted it into place. Working in pairs, one person leveled the window while another secured it to the home's framing.

Finally, ZIP System flashing tape was installed around the window flange to create a watertight assembly. Not shown here, but equally important, the window team applied a custom sill and casing fabricated from Boral TruExterior trim to each window.

When the insulation work begins next week, the insulation company will install expanding polyurethane foam to the gap between the framing and the window, leaving Sunset Green Home with a completed window assembly.

We'll leave you with another aerial shot that shows the changing face of Sunset Green Home's neighborhood. The beautiful home under construction next door by Joe Burns Contracting is another Hurricane Sandy rebuild. Two more homes in the neighborhood have been elevated onto pilings to keep them above the flood plain. I recently wrote about the transformation of the Lower Ninth Ward in New Orleans. All you need to see is the construction activity in the vicinity of Sunset Green Home to know that our neighborhood is changing too.

Photo courtesy JP Hunter